Just like a maestro conducts a symphony, this cutting machine orchestrates single or multiple cuts to suit every need. This includes slicing, grating, and rasping salad leaves and herbs, meat and cooked meat, vegan protein blocks, and baked goods.

The machine’s modern hygienic design allows you to work quickly and easily. Products do not need to be precut, as the machine determines the cutting thickness automatically.

GS 10-2

GS 10-2 is the ultimate all-purpose belt cutting machine for salad, lettuce, vegetables, fruits and herbs. It is ideal for large kitchens, catering and industrial applications. It is easy to use and clean, and is made with high-quality knives that ensure a hygienic, safe cutting process. The GS 10-2 is also available in a free standing version and features castors for maneuverability.

This machine uses sensor technology and a PLC control to reduce waste and cut an extremely wide variety of products. It is easy to operate and clean, and can be used as a stand-alone unit or integrated into a processing line. Its features include an extended infeed belt with optimized hold-down technology and gentle product guidance. It also has a knife box with optimized product rejection, which makes it easy to recycle the product without damaging it. Its inclined surfaces and hygienic stainless steel shaft seals make it easy to maintain, as well.

GS 20

The GS 20 Belt cutting machine is ideal for producing a wide range of cut sizes. Its flexible design makes it suitable for all kinds of produce, including whole heads of lettuce and cabbage, and is easy to clean. The product is fed onto the 250 mm-wide infeed belt depending on the desired cut and then cut precisely and gently thanks to optimized hold-down technology and gentle product guidance. The cut product is then ejected into a container underneath the knife box or optionally conveyed via a discharge belt for further processing.

This allows the production of a large variety of products with great flexibility and at a high output. Depending on the product and the cutting type, up to 4,000 kilograms of food can be processed per hour. In addition, a customized grid cutting device was developed for mango dicing. This allowed Vietnamese food producer HAI THANH to increase the number of mangoes processed per worker from 25 kilograms to 500 kilograms.

VPS-6

A VPS has a fairly quick learning curve and, once an employee understands how it works, it’s relatively safe to use because the blade is encased and remotely controlled. It can also free up the time employees used to spend at the table saw, boosting overall production and workflow. However, some models do have minor accuracy issues, which may occur from hard use or sawdust buildup, so they’re usually best for cutting panels that will be fine-tuned with a CNC router or other type of final work.

The preparation station can support up to six employees. Each has a personal crate holder, plastic cutting board and waste funnel. The upper belt of the preparation station connects seamlessly with the lower belt of the belt cutting machine, which carries products to the knife. The waste disappears through the swan construction of the waste funnel into a large plastic container, which makes the VPS an efficient way to work.

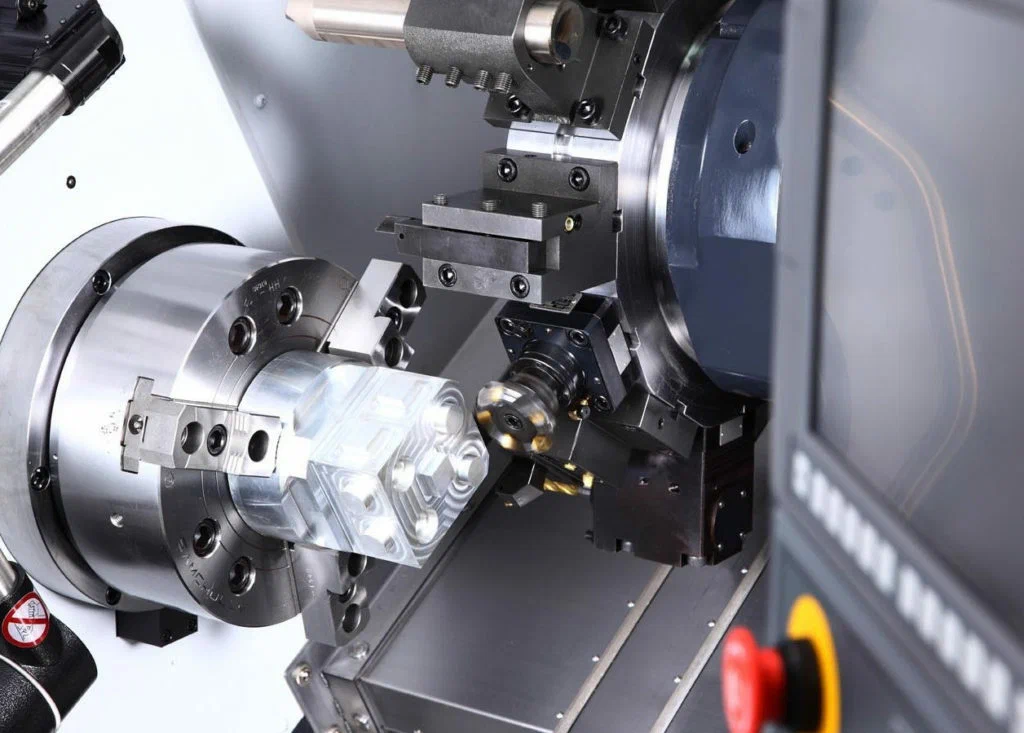

BCM-3000

BCM-3000 is an industrial belt cutting machine suited for medium and large vegetable processing companies that are looking for a high capacity (up to 3000 kg per hour) and don’t want less than exceptional cutting quality, flexibility and ease of use. The wide belt width (275 mm) means that even larger products like cabbage do not need to be precut.

Thanks to the easy switch between knife sets and the adjustable wing knife disc it is possible to process different kinds of leafy vegetables in one pass. The door of the machine and the screen cover over the belts can be opened easily for cleaning. A gas spring is mounted on the cover which makes it very easy to open and prevents it from coming down unexpectedly during the cleaning process.

With the option to choose between hex input mode and black + 6 colors printing the system can be used with most standard laser, matrix and some thermal transfer printers. Programs developed for a certain printer can be used to drive others with little or no software revision.